Change moves fast across worldwide factories. Modern manufacturers now require more than just a digital filing cabinet. They need an engine that powers growth. A robust manufacturing ERP software is that engine. It connects your shop floor to your boardroom in real time.

A recent McKinsey article points out a strategic great divide as companies invest in GenAI but neglect the foundational ERP system capabilities needed to scale these innovations and prevent getting stuck in pilot purgatory.

By 2026, the gap between leaders and laggards will widen significantly. This guide explores the most advanced manufacturing ERP software solutions available today.

In this article, we will explore the 10 best ERP software for manufacturing options that can transform your operations into a high-performance ecosystem.

Why Manufacturing ERP Software is No Longer Just “Software”

In times past, company leaders saw ERP systems for manufacturing mainly as essential overhead tied to paperwork and stock tracking. Not anymore. The year 2026 brings a shift—manufacturing ERP software now operates at the core of business functions. While once limited to finance tasks, today it drives decision-making across departments.

- The tipping point of digital transformation:

Tomorrow’s events take shape through prediction, guided by systems beyond simple recording. But now, insights emerge where data meets intelligent modeling.

- Worldwide presence continues despite interruptions:

Nowhere is stability taken for granted anymore when it comes to moving goods across borders. A system built on centralized digital infrastructure allows oversight at every stage of operation. Platforms linking logistics functions directly to live manufacturing output are gaining attention among those shaping long-term direction.

- The rise of Agentic AI:

Now imagine software that acts without waiting. Rather than follow fixed rules, Agentic AI makes moves based on what happens. When stock runs thin, it triggers new orders. A broken machine? It adjusts the production timeline right away. The old way just showed data. This version jumps in and responds. ERP software for manufacturing stops silent background noise. Instead, it behaves like someone who notices problems and then fixes them.

Read more: 15 Best Free ERP Software Reviewed in 2026

Top 10 Manufacturing ERP Software Solutions for 2026: Ranked & Compared

Besides knowing what you need, picking the best manufacturing ERP software means seeing how tools fit real tasks. Equal performance across platforms? Rare. Where one handles intricate aircraft parts smoothly, another powers through mass-produced retail items without delay.

Comparison Table: Strategic Matrix of The Best Manufacturing ERP Systems (2026)

Tool | Primary use case | AI Capabilities | Pricing |

|---|---|---|---|

SAP S/4HANA Manufacturing | Intelligent manufacturing operations | Embedded AI, predictive planning, demand forecasting, Joule copilot | $200 per user/mo + $75,000 implementation costs. |

|

Oracle NetSuite ERP |

Cloud ERP for scaling manufacturers |

AI pricing insights, demand forecasting, Advanced Pricing engine |

Available via Demo. |

|

Microsoft Dynamics 365 Business Central |

SMB manufacturing & supply chain |

Copilot AI, predictive analytics, automated workflows |

Essentials $80 per user/mo, Premium $110/user/mo |

|

Epicor Kinetic |

Smart manufacturing & distribution |

Available via Demo. | |

|

Infor CloudSuite Industrial |

SMB industrial manufacturing |

Available via Demo. | |

|

Acumatica Manufacturing Edition |

Flexible manufacturing ERP software |

Consumption-based. | |

|

Plex Smart Manufacturing Platform |

End-to-end smart manufacturing |

Available via Demo. | |

|

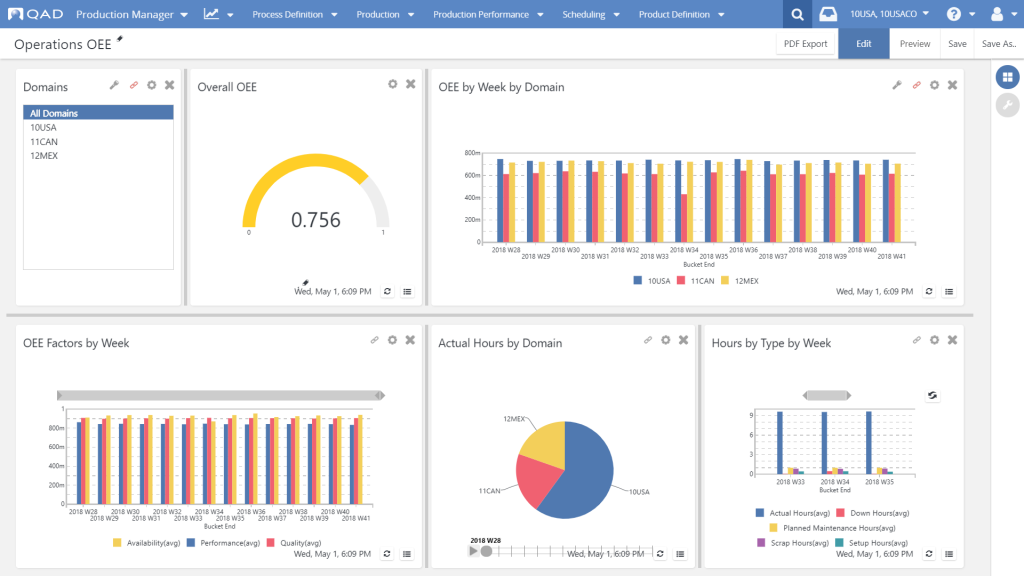

QAD Adaptive ERP |

Global manufacturing operations | ||

|

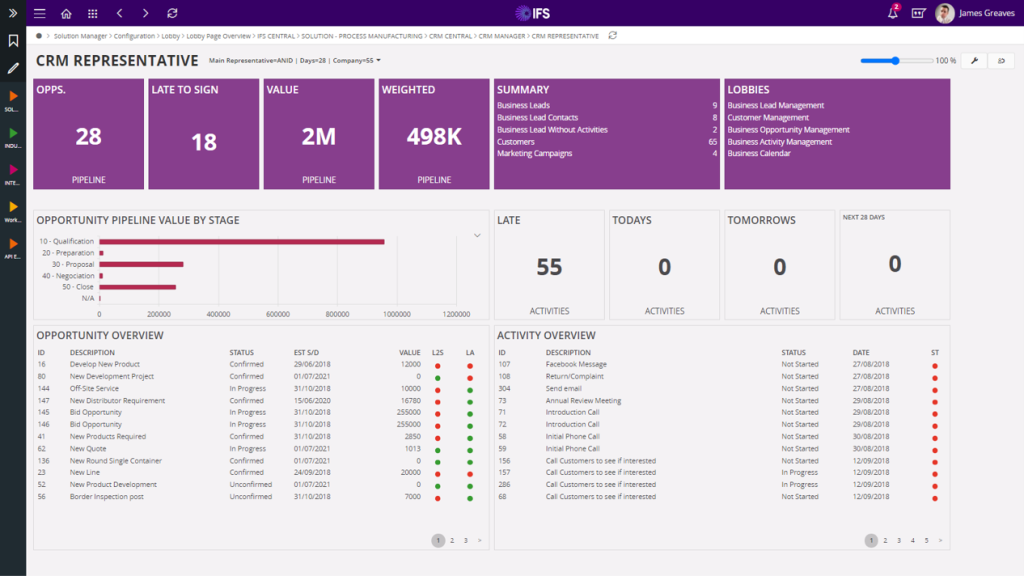

IFS Cloud |

Asset-intensive manufacturing |

Available via Demo. | |

|

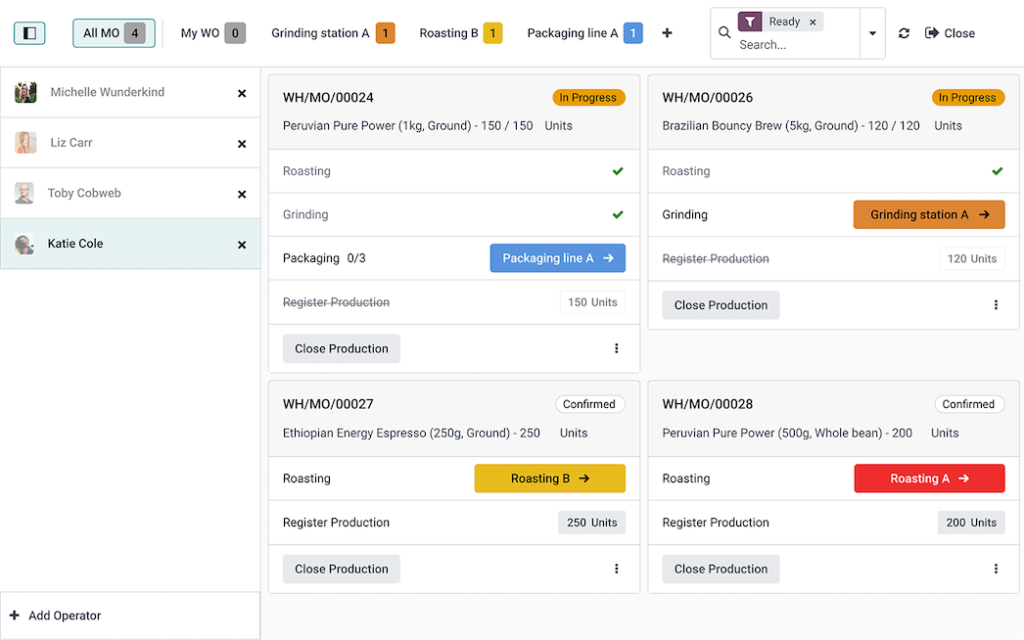

Odoo Manufacturing |

Affordable MRP for SMB production |

AI agents, production planning, natural language reports |

Available via Demo. |

This article provides you with a focused look at current ERP software capabilities, but maintaining operational excellence in the uncertain future means staying ahead of rapid technological shifts and competitor advancements. Subscribe to Digest.Pro so your business never misses a critical industry breakthrough or emerging tech trend.

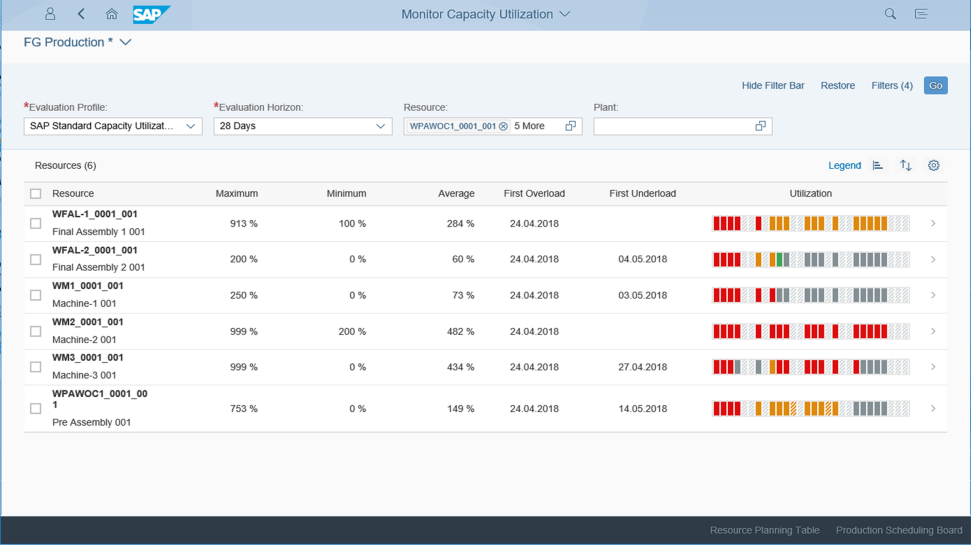

1. SAP S/4HANA Manufacturing

SAP is the gold standard for global enterprises, especially for large organizations. This is a manufacturing ERP system that uses in-memory database technology for extraordinary speed. It easily handles massive data sets.

Best for:

Global conglomerates with complex, multiple sites.

Key features:

- Advanced predictive material requirements planning.

- Real-time inventory management visibility across global warehouse networks.

- Integration with IoT production process monitoring sensors.

- Comprehensive quality compliance management modules.

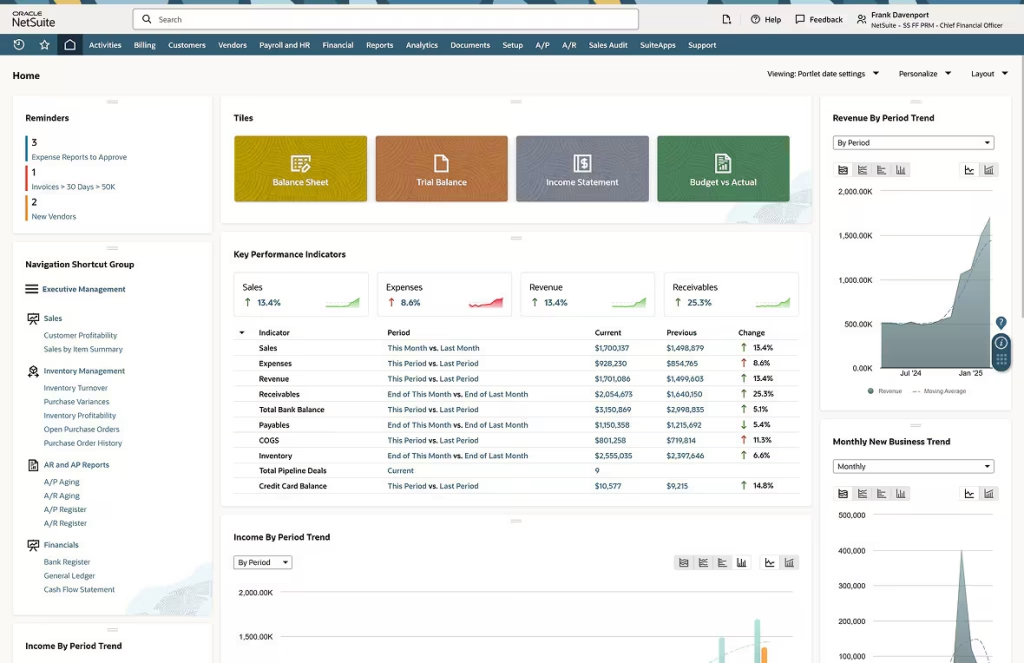

2. Oracle NetSuite ERP

For mid-sized manufacturers, NetSuite is the greatest cloud-based ERP software for manufacturing. It provides a single platform that grows with you. It is most renowned for being user-friendly and versatile.

Best for:

Rapidly expanding manufacturing firms are in need of cloud-based ERP software for manufacturing that is scalable.

Key features:

- Financials and customer relationship management were combined.

- Automated bill cycles, order processing, etc.

- Visibility of the whole supply chain in real time.

- Sophisticated inventory management that supports several locations.

- C-level reporting using native business intelligence tools.

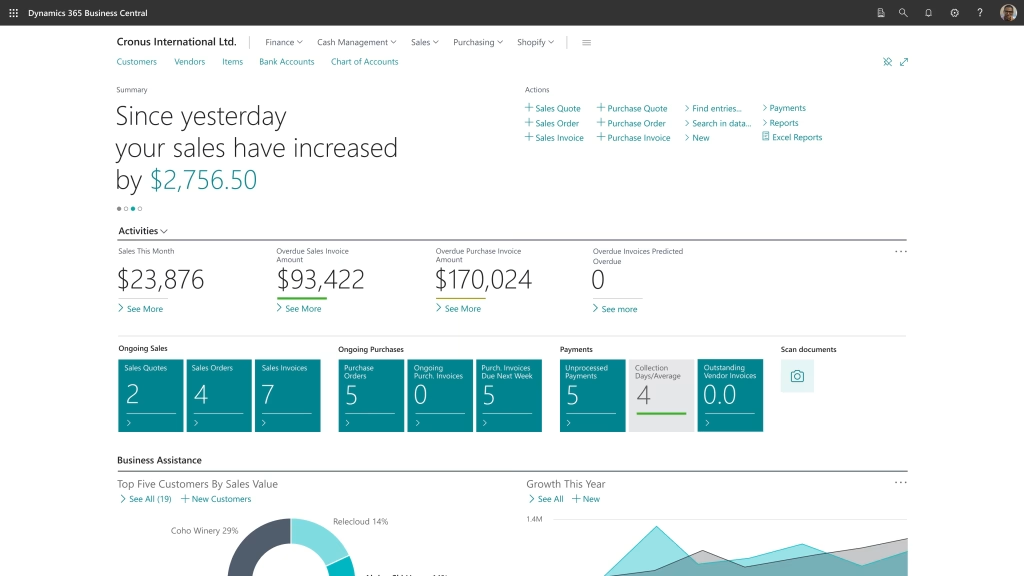

3. Microsoft Dynamics 365 Business Central

For many businesses, Microsoft provides a familiar ecosystem. Office 365 and Azure are seamlessly integrated with this ERP software for manufacturing solutions. It offers a business management approach that is modular.

Best for:

Small- to medium-sized producers seeking a recognizable user interface.

Key features:

- Smooth analytics integration with Microsoft Power BI.

- Tools for flexible production scheduling and planning.

- Strong warehouse management capabilities for inventory.

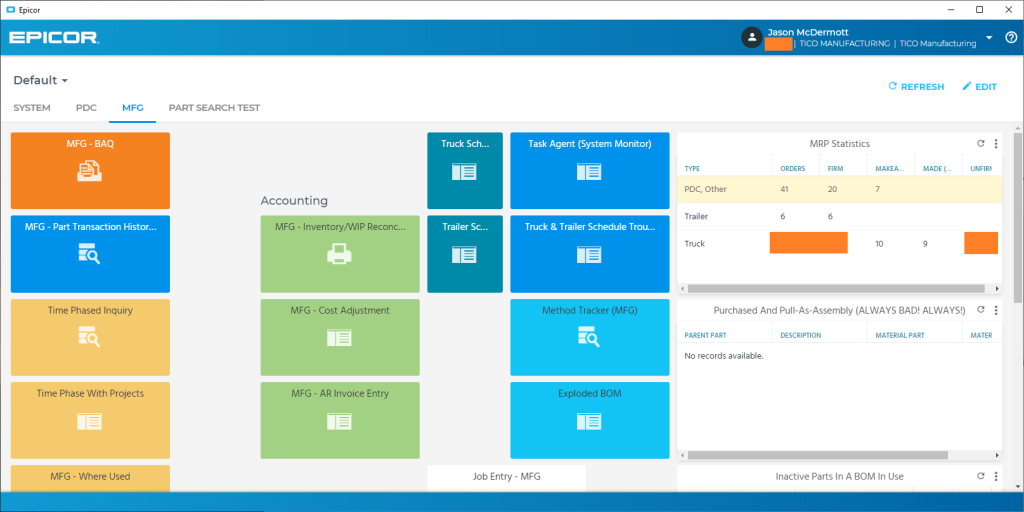

4. Epicor Kinetic

Epicor has built manufacturing ERP software specifically for the industry. It is not a generic tool adapted for factories. It is a dedicated ERP software for manufacturing.

Best for:

Independent producers in the medical device, aerospace, and automotive industries.

Key features:

- Product lifecycle management (PLM) is integrated.

- Thorough time-tracking of shop floor production.

- Assistance with intricate make-to-order (MTO) procedures.

- Mobile-first design for shop floor operators.

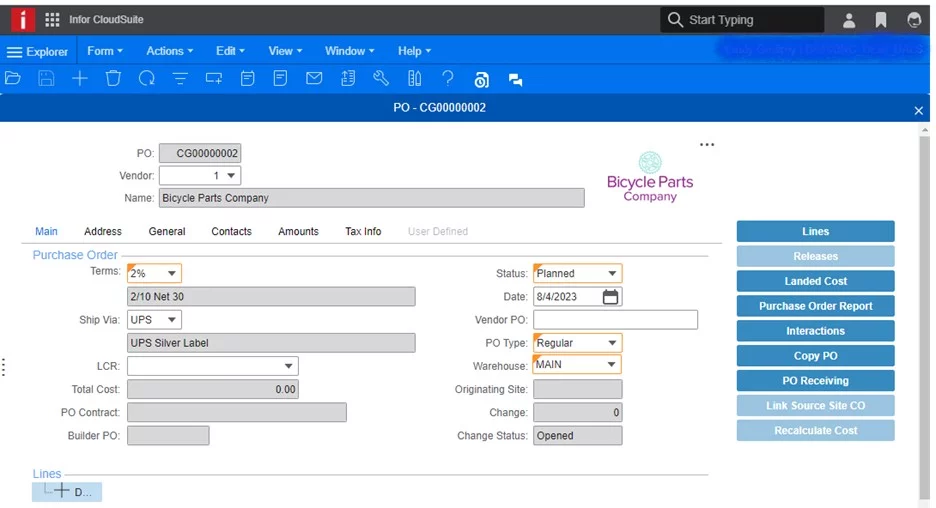

5. Infor CloudSuite Industrial

Infor provides highly specialized ERP software for manufacturing that business leaders trust. It focuses on specific micro-verticals. The platform is built on Amazon Web Services (AWS) for maximum reliability.

Best for:

Specialized industrial manufacturing and heavy equipment.

Key features:

- Role-based dashboards for specific job functions.

- Industry-specific compliance and regulatory tools.

- Strong supply chain management collaboration features.

- Advanced planning and scheduling (APS) logic.

- Integrated asset management for factory machinery.

- Global financial consolidation tools.

Read more: 15 Best ERP Software for Small Businesses Reviewed in 2026

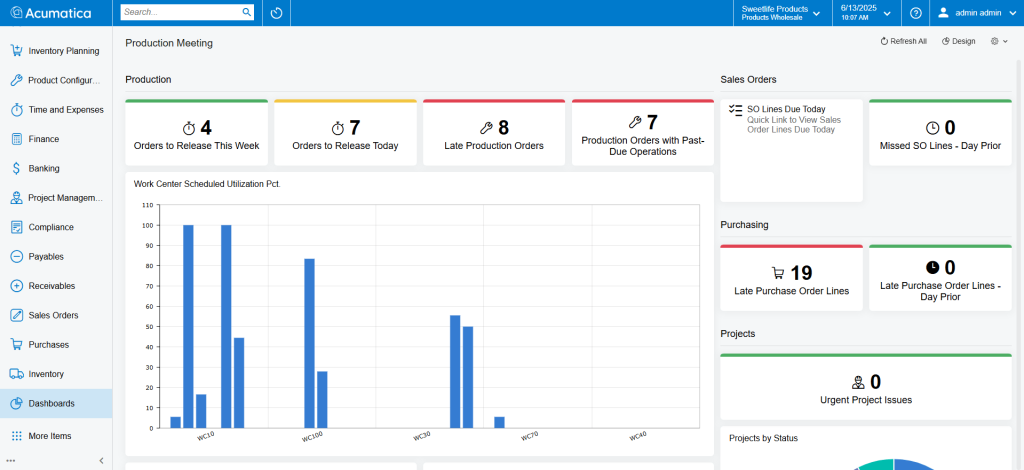

6. Acumatica Manufacturing Edition

Acumatica is a modern cloud-based manufacturing ERP solution with a unique pricing structure. They don’t charge per user. Their pricing structure is consumption-based.

Best for:

Mid-market manufacturers who need unlimited user access.

Key features:

- Full integration between the shop floor and financials.

- Visual production planning and scheduling boards.

- Comprehensive Bill of Materials (BOM) management.

- Real-time data synchronization across all devices.

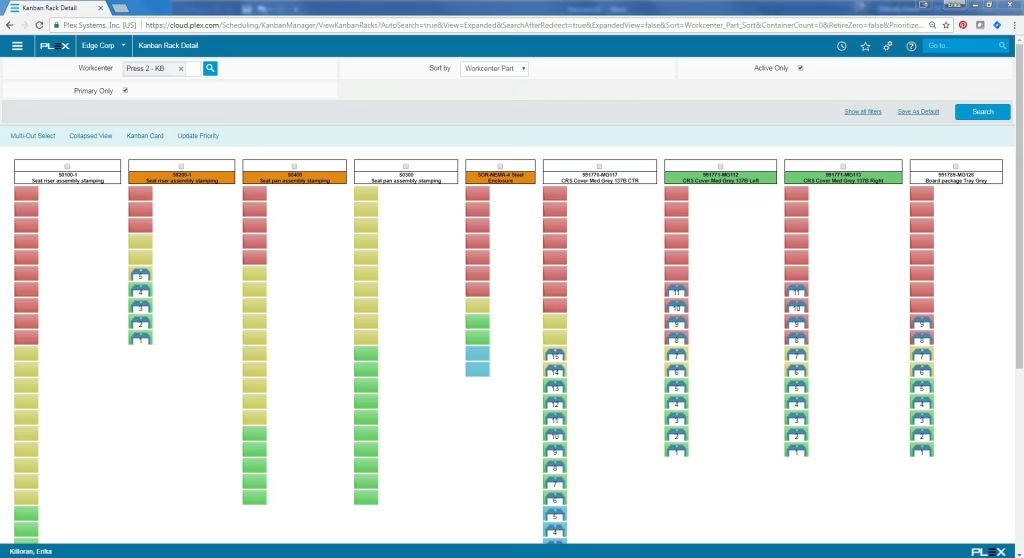

7. Plex Smart Manufacturing Platform

Plex offers a unique approach to ERP software for manufacturing. It is a cloud-native platform that connects every inch of the plant.

Best for:

Automotive and food/beverage manufacturers require strict quality control.

Key features:

- High-frequency time production monitoring.

- Built-in Quality Management System (QMS).

- Digital twins for production line simulation.

- Paperless shop floor environment.

- Automated compliance reporting for ISO and FDA standards.

8. QAD Adaptive ERP

QAD focuses on agility. Their manufacturing ERP system is designed for the “Adaptive Enterprise.” It helps companies respond quickly to market changes.

Best for:

Life sciences and high-tech manufacturers.

Key features:

- Flexible architecture that adapts to business changes.

- Powerful supply chain management visibility.

- Integrated international trade and logistics tools.

9. IFS Cloud

IFS provides a single-platform ERP software for manufacturing solutions and asset management. It is ideal for companies that manufacture, sell, and service complex products.

Best for:

Asset-intensive industries and project-based manufacturing.

Key features:

- Unified solution for ERP, EAM, and service management.

- Native support for Field Service Management (FSM).

- Advanced project accounting for long-term builds.

- Embedded sustainable manufacturing metrics.

- Powerful AI for resource optimization.

10. Odoo Manufacturing

Odoo is an open-source manufacturing ERP solution that has gained massive popularity. It is modular and highly affordable.

Best for:

Startups and small manufacturers need a cost-effective entry point.

Key features:

- Simple design reduces the need for instruction.

- Seamless integration between BOM, PLM, and maintenance.

- Real-time communication tools for team collaboration.

- Stock restocking occurs automatically through programmed rules.

- Integrated website and e-commerce modules.

Read more: Top 67 Startups in Germany to Watch 2026: AI, Unicorns & GreenTech Leaders.

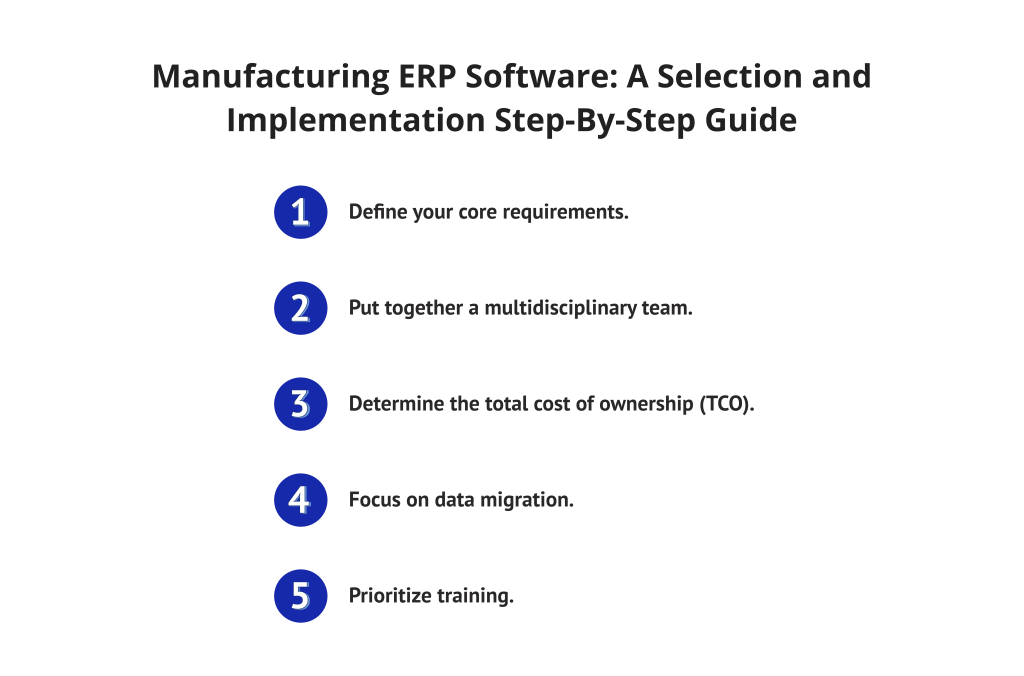

Manufacturing ERP Software: A Selection and Implementation Step-By-Step Guide

Implementing a modern ERP system is a significant undertaking. Most failures happen during the planning stage. You must approach this as a business transformation, not just an IT project.

- Define your core requirements. Every manufacturing ERP buyer’s guide emphasizes this step. Assess whether real-time production monitoring is your top priority or if you require improved inventory control. Before looking at vendors, decide which features are essential.

- Put together a multidisciplinary team. Incorporate executives from IT, production, and finance. This guarantees that the ERP implementation meets everyone’s needs. The system will not work if the shop floor does not support it.

- Determine the total cost of ownership (TCO). Typically, a cloud-based ERP solution for manufacturing has higher monthly fees but lower upfront costs. Contrast this with expensive on-premise systems. Consider more than just the initial cost; consider the long-term return on investment.

- Focus on data migration. Your new manufacturing ERP system is only as good as the data you put into it. Clean your legacy data before the move. This prevents “garbage in, garbage out” scenarios.

- Prioritize training. Even the top manufacturing ERP software is useless if employees do not know how to use it. Invest in continuous education. This ensures your team can leverage the full power of the manufacturing ERP software solutions.

Read more: Top 51 Startups in Poland to Watch in 2026: Investment Executive Guide.

Conclusion: Future-Proofing Your Manufacturing Business

Choosing to update your ERP system involves long-term thinking. By 2026, delay becomes a liability. Rivals operate at a higher speed and greater precision. Because of this, new capabilities matter more. Progress rests on systems that adapt without constant oversight.

Efficiency emerges where structure supports change. Future readiness begins with backend strength. Systems shape outcomes more quietly than expected. Growth follows design, not just effort.

Navigating the complexities of the 2026 manufacturing landscape requires staying informed on rapid technological shifts. To receive weekly expert insights and strategic updates on digital transformation, subscribe to Digest.Pro.

Frequently Asked Questions: Manufacturing ERP Software FAQs

Depending on the company scale and sector, ideal systems differ. For massive international operations, SAP S/4HANA performs well. Discrete manufacturers often find a better fit with Epicor Kinetic. Mid-market firms using cloud platforms tend toward Oracle NetSuite.

Plex delivers integration capabilities recognized across manufacturing sectors. Visibility into production activity happens instantly when systems link properly. The connection between operational data and financial records within ERP occurs without delay. Integration depth matters where execution meets business planning.

Repetitive, Discrete, Job Shop, Continuous, and Batch are the five primary processes. Your particular process type must be supported by your ERP software for manufacturing.

Autonomous choices may define what comes next, replacing simple data logging. Decisions made by machines could emerge through deeper links with connected sensors. Digital replicas might fit into daily operations as a matter of course. What follows will shift how systems behave—less passive, more active in response.

Most often, one finds Casting alongside Molding, followed by Machining, and then Joining takes place before Forming appears. Tracking of material flow and cost movement happens within modern ERP systems regardless of the method used.

Heavy dependence on spreadsheets often signals limitations. Inventory mistakes occur more regularly when tools are outdated. Real-time insight becomes missing once operations grow beyond manual methods. Minutes spent waiting for a production summary suggest that current systems no longer match needs.

A generic enterprise system emphasizes back-office operations through its focus on financial management and human resource administration, yet a manufacturing-specific solution exists to support operations on the shop floor. These platforms provide the necessary technical capabilities that enable users to handle complex product hierarchies and exact production timelines. They also maintain strict quality control standards.

The ERP implementation process depends on company size, area, and type, but typically, implementation takes 6 to 18 months.

Fear around data safety often shadows cloud systems. Still, encryption standards today meet strict industry demands. Proprietary workflows gain protection through layered access controls. Trust grows when audit trails record every change. Risk shrinks under constant monitoring protocols.

Now, AI helps ERP software move beyond storing data to making moves. Because predictions about repairs come before failures happen, operations adjust ahead of time. When delays could appear, scheduling shifts on its own. This response happens without waiting, driven by patterns found in flows of information. Instead of just tracking, the system begins acting.

Our Methodology: How We Ranked the Top Manufacturing ERP Software

We employ a standardized and analytical approach to our rankings research. We look at more than 50 ERP software vendors and base our rankings on 5 different pillars:

- Industry specificity: We looked for software designed specifically for ERP software for manufacturing.

- Innovation and AI: We looked for software that includes agentic AI and predictive analytics.

- Scalability: We looked at how manufacturing ERP solutions expand with the business.

- User experience: We examined the user interfaces on desktop and mobile and tried them for ease and simplicity.

- Market presence and ROI: We looked at analyst reports from Gartner and McKinsey to assess actual results.

References

- Gartner, Inc. (2025). Magic Quadrant for Cloud ERP for Product-Centric Enterprises.

- McKinsey & Company. (2024). The Future of Industry 4.0: Smart Manufacturing at Scale.

- Deloitte. (2025). Manufacturing Industry Outlook: Strategic Trends for 2026.

- IEEE Xplore. (2024). Blockchain and IoT Integration in Modern Manufacturing ERP.

- Aman, M., & Rashid, M. A. (2022). Open Source ERP Systems: Benefits and Challenges for SMEs. Google Scholar.

- Forrester Research. (2024). The State of Digital Operations and ERP.

- Alan R. Peslak, Girish H. Subramanian & George E. Clayton (2016). “The Phases of ERP Software Implementation and Maintenance: A Model for Predicting Preferred ERP Use.”

- Hussain Abdul Nabi, Ali Abbas Hussain, Abdul Karim Sajid Ali, and Haroon Arif (The Asian Bulletin of Big Data Management Journal, 2025). “Data-Driven ERP Solutions Integrated with AI for Streamlined Marketing Operations and Resilient Supply Chain Networks.”